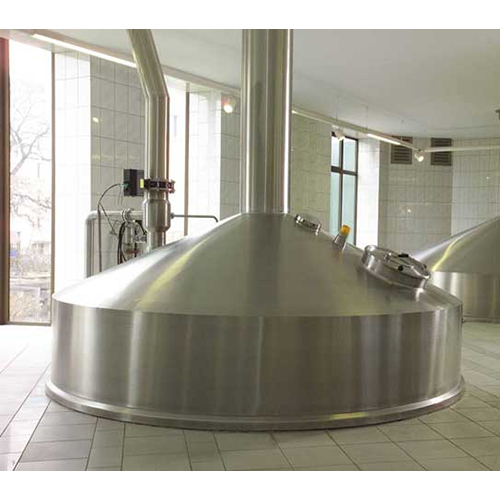

About Mash Kettle

Mash Kettle is a vessel required in the brewing process to heat and mix the mash, a combination of grains and hot water. The mash kettle is typically made of stainless steel or copper and may be either electric or gas-heated. During the brewing process, the grains are added to the mash kettle along with hot water, and the mixture is stirred to create a consistent mixture. The mash kettle is also used to maintain a constant temperature during the mashing process, which is critical to ensuring the enzymes break down the starch into fermentable sugars. Overall, the use of a mash kettle is an essential part of the brewing process and ensures that beer is brewed to quality standards.

Engineered for EfficiencyThis mash kettle blends industrial performance with practicality. Its stainless steel construction provides durability, while the automatic operation optimizes workflow. Designed to handle demanding applications, it supports a voltage range of 220-440V and requires no built-in computers, making it simple to operate and maintain for factories and breweries.

Versatile and Reliable InstallationWith a free-standing design, the mash kettle can be positioned wherever suits your space. It is manufactured to suit a wide array of industrial environments, whether implemented by distributors, suppliers, or direct users throughout India. The combination of automatic operation and premium materials means lower downtime and consistent results.

FAQ's of Mash Kettle:

Q: How is the mash kettle installed in an industrial setting?

A: The mash kettle features a freestanding installation type, allowing it to be conveniently placed wherever there is sufficient space and access to a 220-440V power supply. Its design eliminates the need for complex mounting or fixed infrastructure.

Q: What materials are used in the mash kettle, and why are they beneficial?

A: Constructed from high-grade stainless steel, this mash kettle is highly durable and resistant to corrosion. The material ensures hygiene, longevity, and ease of cleaning, making it ideal for industrial mashing and brewing processes.

Q: When should I consider using an automatic mash kettle for my operations?

A: An automatic mash kettle is ideal when you require consistent processing, reduced manual intervention, and increased productivity. It is particularly beneficial for breweries, food processing plants, and other industries where repeated, large-batch mashing is essential.

Q: Where can this mash kettle be sourced in India?

A: The mash kettle is readily available throughout India, offered by distributors, exporters, manufacturers, suppliers, and traders. This ensures you can source it efficiently according to your industrial requirements and location.

Q: What is the typical usage process for this mash kettle?

A: Users simply connect the kettle to an appropriate 220-440V power source and load the ingredients. The automatic features manage the mashing process, ensuring efficiency and consistent output without the need for computer controls.

Q: How does automatic operation benefit industrial users?

A: Automatic operation streamlines the mashing process, minimizes human error, and improves consistency. This leads to higher productivity, reduced labor costs, and more reliable results in each batch.