About SS304 CIP System

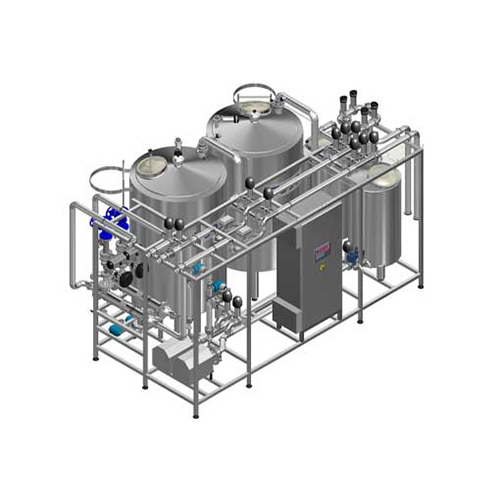

SS304 CIP System is utilized in the food and beverage industry, as well as in other industries that require thorough cleaning of equipment and piping. The CIP system is designed to efficiently and effectively clean equipment without the need for disassembly, ensuring optimal sanitation and minimizing downtime. The system is composed of tanks, spray heads, pumps, valves, and instrumentation, all made of stainless steel for durability and corrosion resistance. In general, the SS304 CIP system is an essential tool to maintain the quality and safety of products and processes in various industries.

Efficient Industrial CleaningOur SS304 CIP System streamlines the cleaning process for food processing equipment, delivering automated and consistent hygiene with minimal human intervention. Its stainless steel build ensures durability and resistance to frequent washing chemicals, making it an essential asset for maintaining strict industry standards.

User-Friendly OperationThis system offers automatic functionality without the need for computerized controls, making it simple to operate and maintain for industrial staff in diverse food processing settings. Its free-standing installation design allows easy placement and integration into existing floor plans.

Sustainable PerformanceDesigned with eco-friendliness in mind, the SS304 CIP System minimizes water and chemical use during cleaning cycles. This not only reduces operational costs but also aligns with sustainability objectives for modern food production environments.

FAQ's of SS304 CIP System:

Q: How is the SS304 CIP System installed in an industrial setting?

A: The SS304 CIP System is designed as a free-standing unit, allowing for straightforward placement without requiring complex mounting or integration. Installation involves connecting water, power (220-440V), and necessary piping, making it suitable for various factory layouts.

Q: What type of food processing industries can use this CIP System?

A: This CIP System is ideal for a wide range of food processing industries, including dairies, breweries, and beverage plants. It is engineered for any facility that demands consistent, efficient hygiene for equipment and processing lines.

Q: When should the CIP System be operated during production cycles?

A: The SS304 CIP System is typically used between or after production batches, or whenever equipment hygiene is necessary to prevent contamination. Its automated process ensures thorough cleaning while minimizing downtime.

Q: Where can I source this SS304 CIP System in India?

A: You can obtain this system from authorized distributors, exporters, manufacturers, suppliers, and traders across India. Look for vendors with proven expertise in industrial food equipment for quality assurance and after-sales support.

Q: What is the cleaning process like with this automatic CIP System?

A: Once set, the automated CIP System runs programmed cleaning cycles using water and cleaning agents, efficiently washing internal surfaces of processing equipment. Its design ensures even hard-to-reach areas are sanitized without dismantling equipment.

Q: How does using this CIP System benefit my food processing operation?

A: Implementing the SS304 CIP System enhances operational efficiency by reducing manual labor, minimizing resource usage, and ensuring consistent cleaning standards. Its eco-friendly and durable design also helps lower overall maintenance and operating costs.